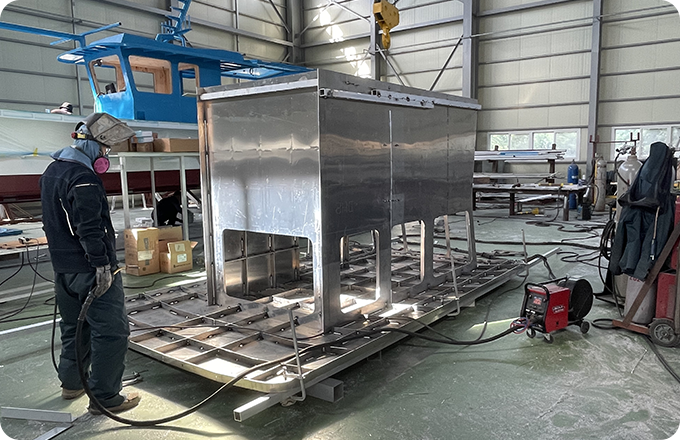

Assembling and tack welding frames

Prepairing process for main welding after tack welding to facilitate installation of the hull shell plate. Based on a 3D blue-print, we align frames with samewidth in

Continuous welding is preformed on all frames except bulkheads based on KOMSA regulations

The wateright bulkhead is welded with glue so that the hull VOID zone can be set

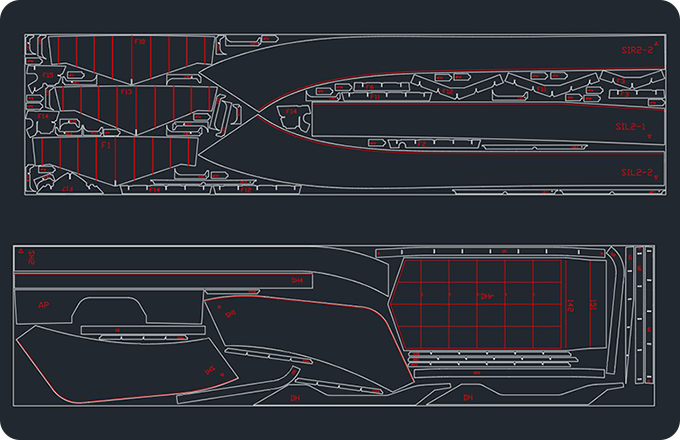

Assembling the parts with tack welding technic from the head of the stern based on the marked line on separate outer plates

As it is a three-dimensional curve in the direction to the bow, it is difficult to form the shape. Tak welding the frames one point at a time to complete the curvy bow outline

Assemble in the order of Bottom, Chine, Side

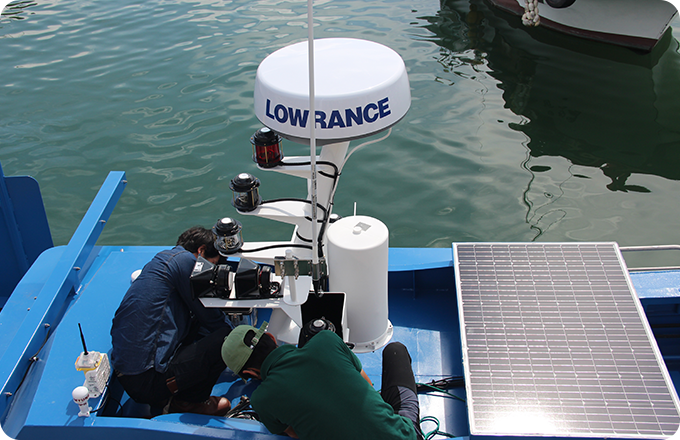

Inspection for the possible defect of the aluminum vessel

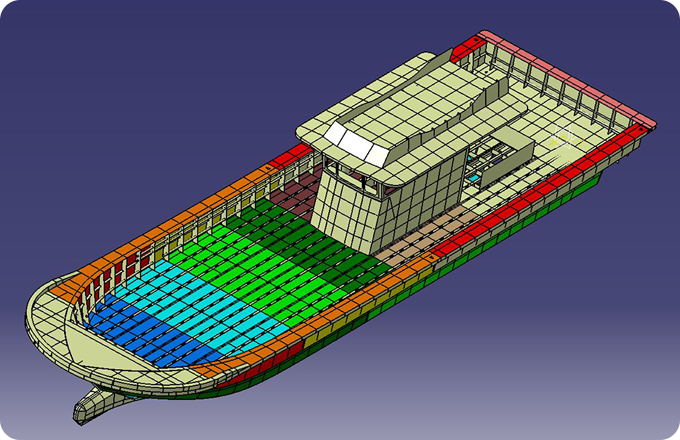

After assembling the hull shell plate, turn the hull to assemble the upper deck

Upper deck assembly and welding

For upper deck welding, the slot welding method was selected because the depth of the hell was too low to weld from the inside.Also welding will be done by connecting frame in slot dug at regular